candela spa

TACUARA DISEÑO EN BAMBÚ and the architect Luis Santiago Montoya Ramírez designed the CANDELA SPA project. My contribution came during in the construction phase, redesigning the project in Grasshopper to improve the workflow on the construction site and providing hands on support to the prefabrication, assembly, and painting of bamboo parts. This project reflects a combination of my knowledge of parametric tools with a long standing interest in vernacular building techniques, which led me to spend three months in Colombia volunteering with the Tacuara team.

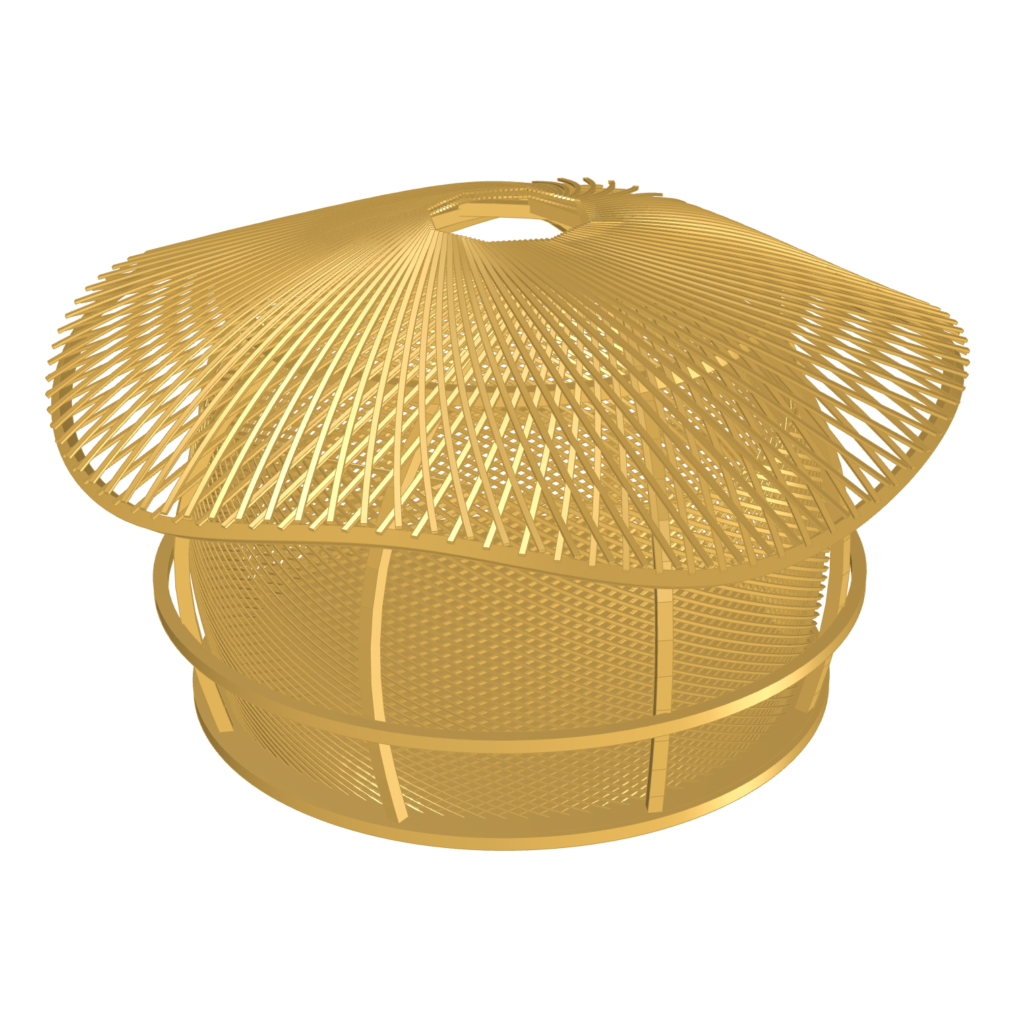

The project is under construction and consists of a spa with five capsules and one tunnel that connects them. The first capsule is the reception, and the other capsules are the massage rooms. During construction, my work was divided into two stages. The first was the prefabrication of beams and pillars, and building the physical model. At this stage, I had contact with bamboo treatment techniques, cutting it into strips and constructing beams and pillars from the junction of several bamboo strips. The bamboo they use is the guadua angustifolia, native to Colombia. In the second phase, I redesigned the project in Grasshopper to determine the amount of bamboo we would need to make the woven wall and the guides with angles and measurements for placing the woven wall. I also participated in assembling the woven walls, placement of the ceiling and painting.

What caught my attention in this project was that while digital tools are very useful in managing workflows, an attentive look at the material properties is very important especially when using heterogeneous materials such as bamboo. We must respect the limit of each bamboo strip, choosing the thinnest ones for parts that require greater flexibility and the thickest ones for structural parts. Digital tools can help predict this when we do curvature tests, for example, but a careful eye is essential

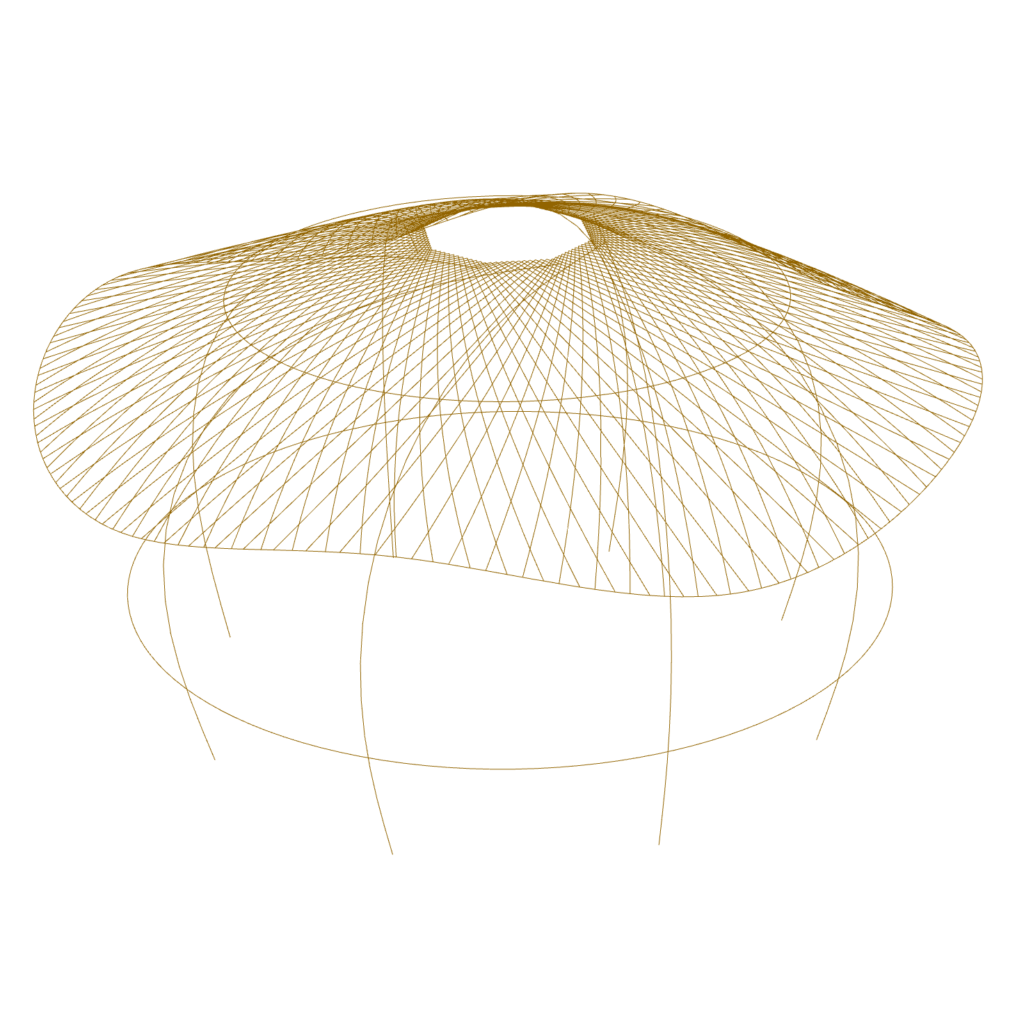

redesign process in grasshopper

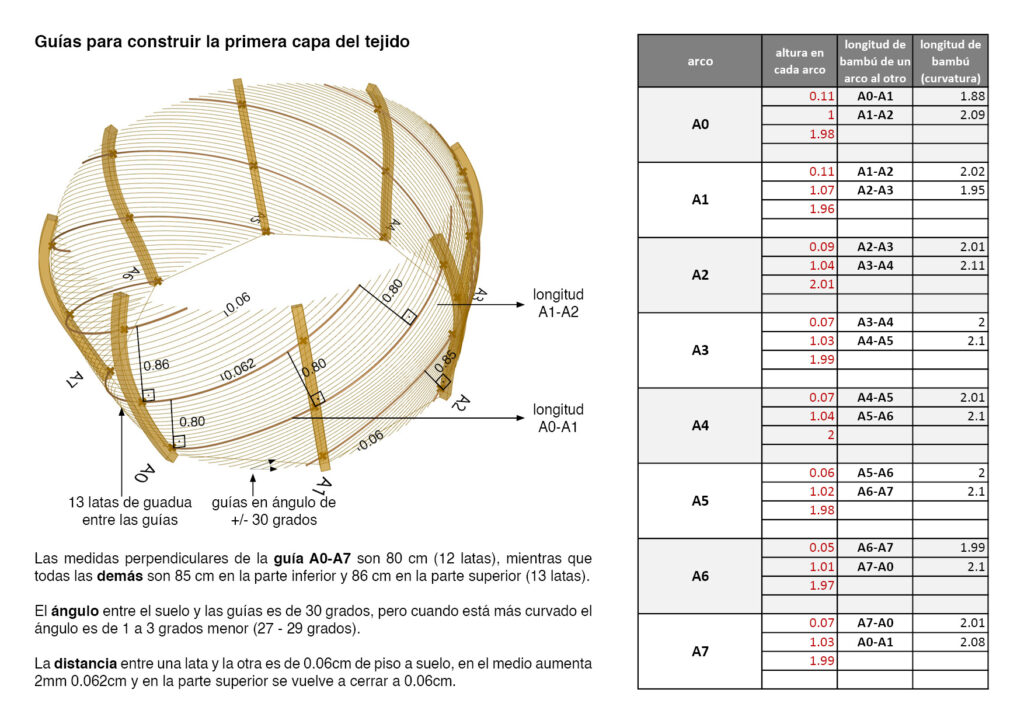

construction guides for the woven wall

photos of the 3 project phases: model, manufacture and assembly on site

team

Date: January-March 2023

Location: San Jerónimo, Colombia

Project Architect:

Luis Santiago M. Ramírez

Tacuara leaders:

Camila Dutra

Urabá del Sol Ponzone

Tacuara team:

Exneider Madrid, Alvaro López, Adolfo Salazar, Jeimer Guarin, Fernando Enamorado, Cristian Morales, Camilo Ocampo

Volunteers:

Camila Calegari Marques, Juliana Saenz, Paola de Gracia, German Castillo, Nicole Figueroa and Yessica Arboleda.