teaching parametric design for bamboo construction

guadua pavilion

type: bamboo construction

role: computational designer, construction manager and teacher

collaboration: Tacuara Diseño en Bambú

location: San Rafael, Colombia

year: 2023

The guadua pavilion was developed in partnership with Mansur Arevalo and Tacuara Diseño en Bambú as part of the course “Exploring Organic Geometry with Bamboo: Parametric Design with Rhino and Grasshopper.” Aside from conceptualizing the course and co-leading the teaching, my role involved guiding students through designing and building a temporary bamboo shell initially conceived as an exercise during my master’s degree in Parametric Design at UPC in 2018.

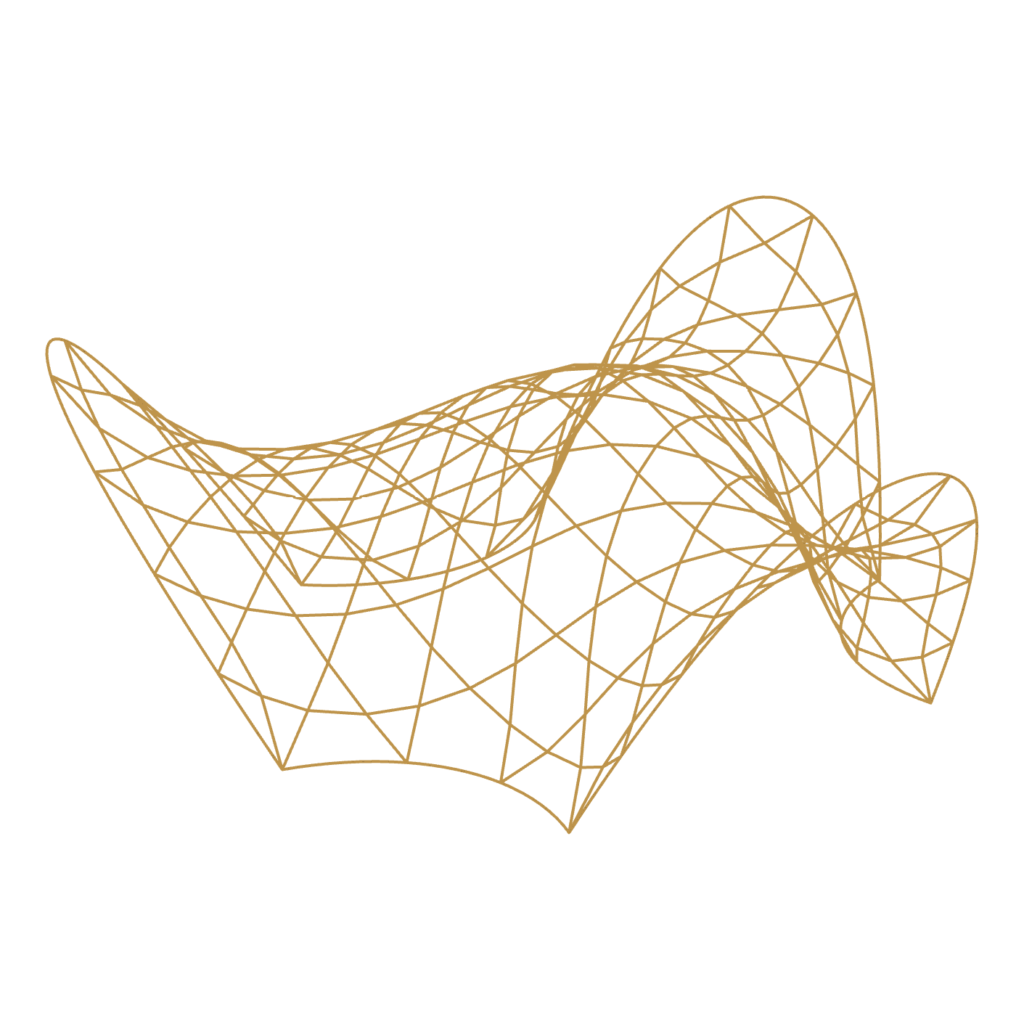

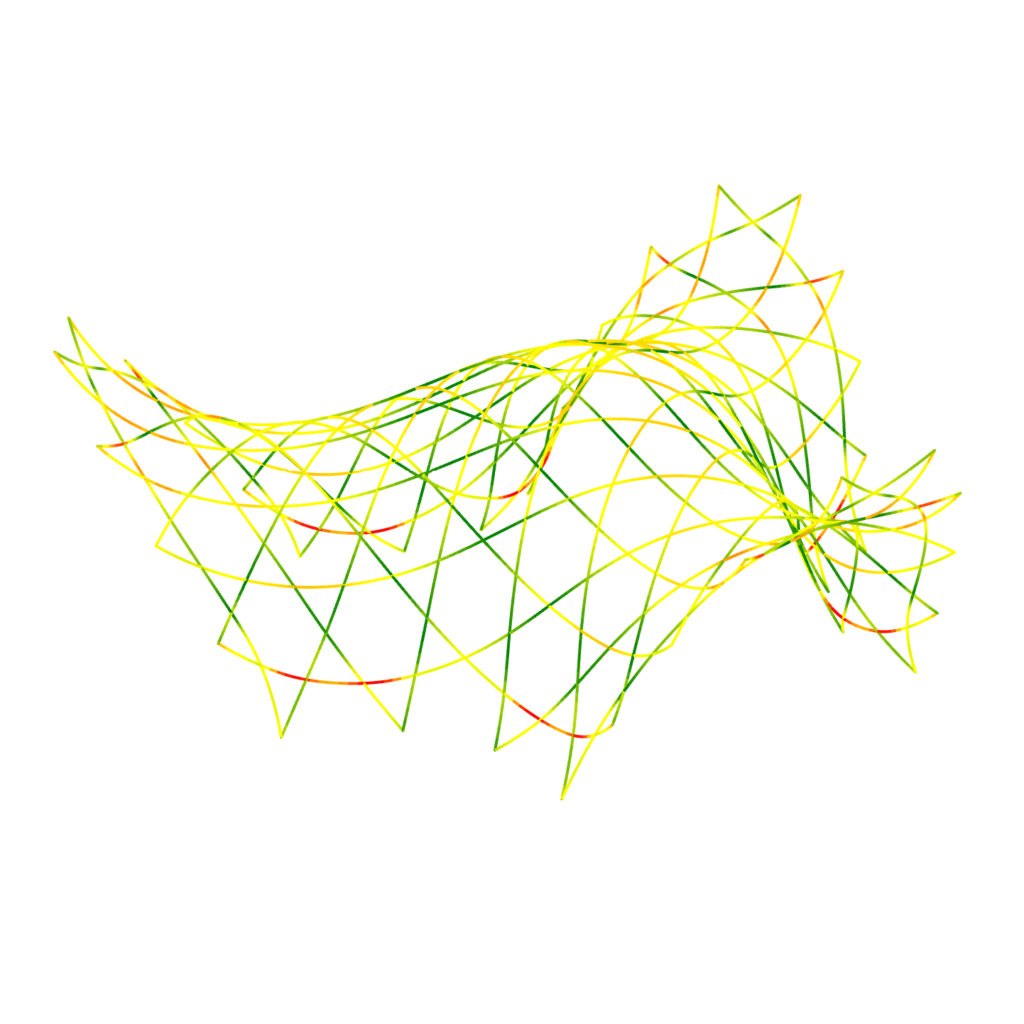

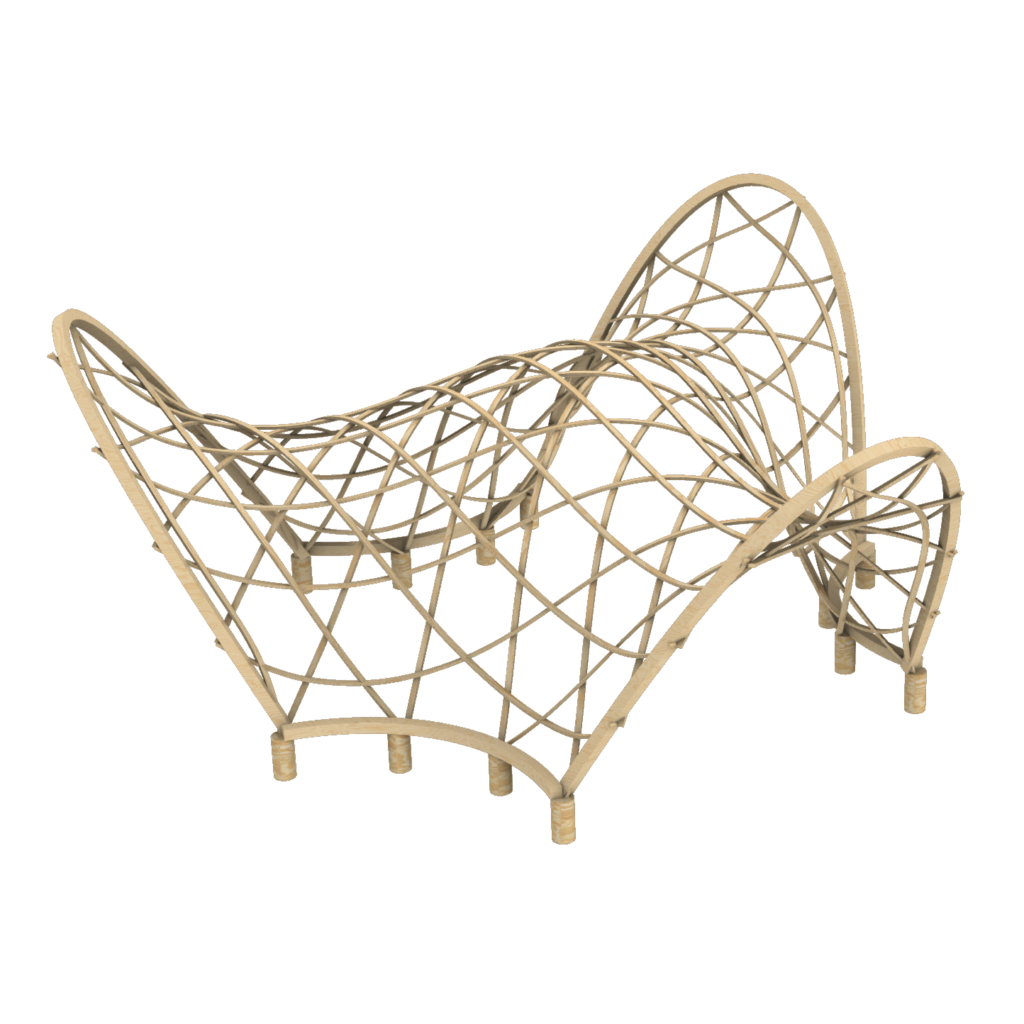

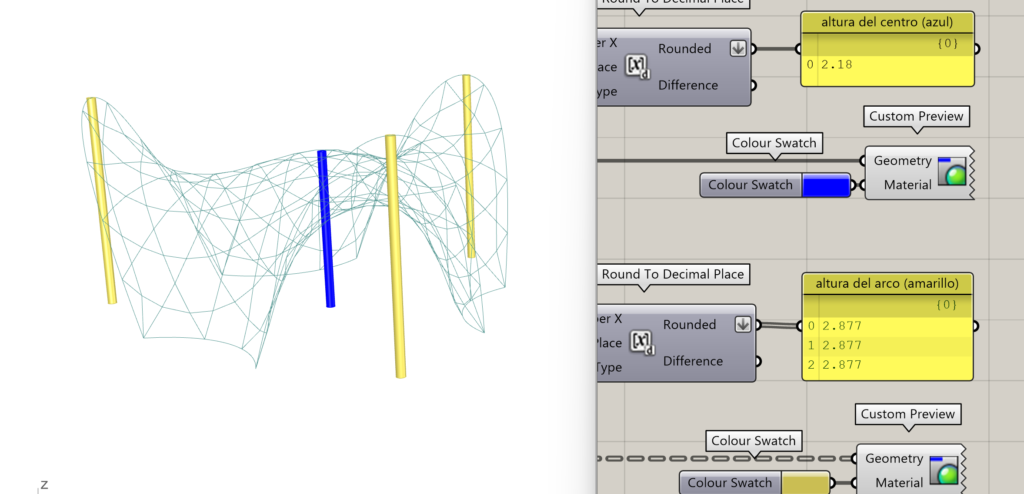

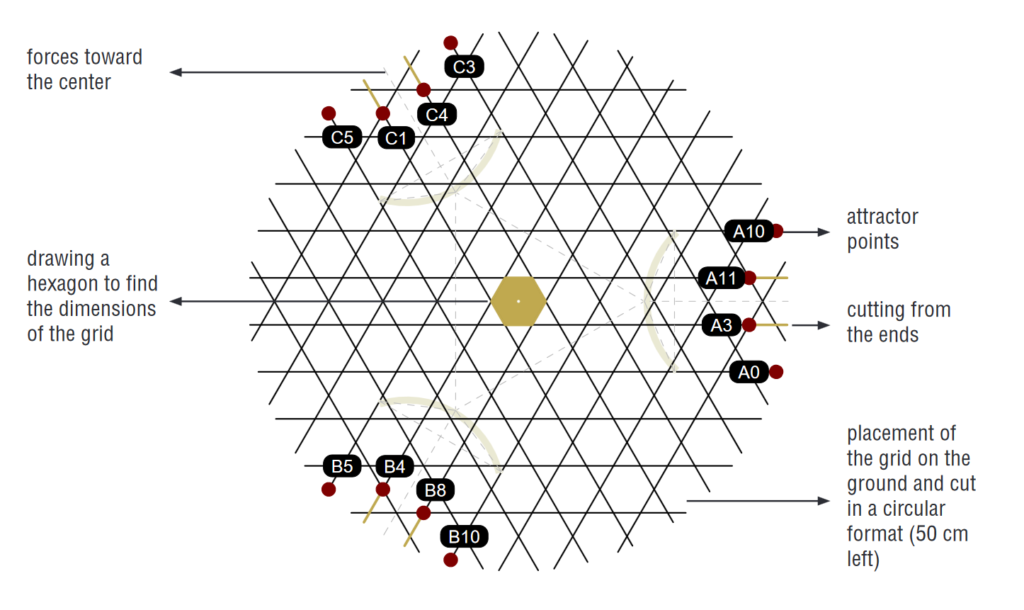

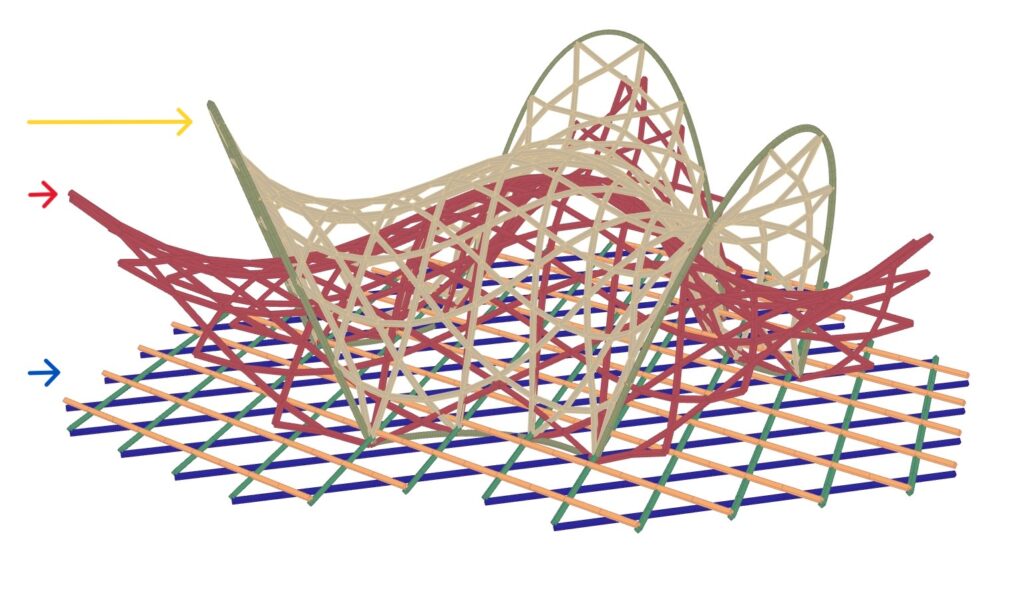

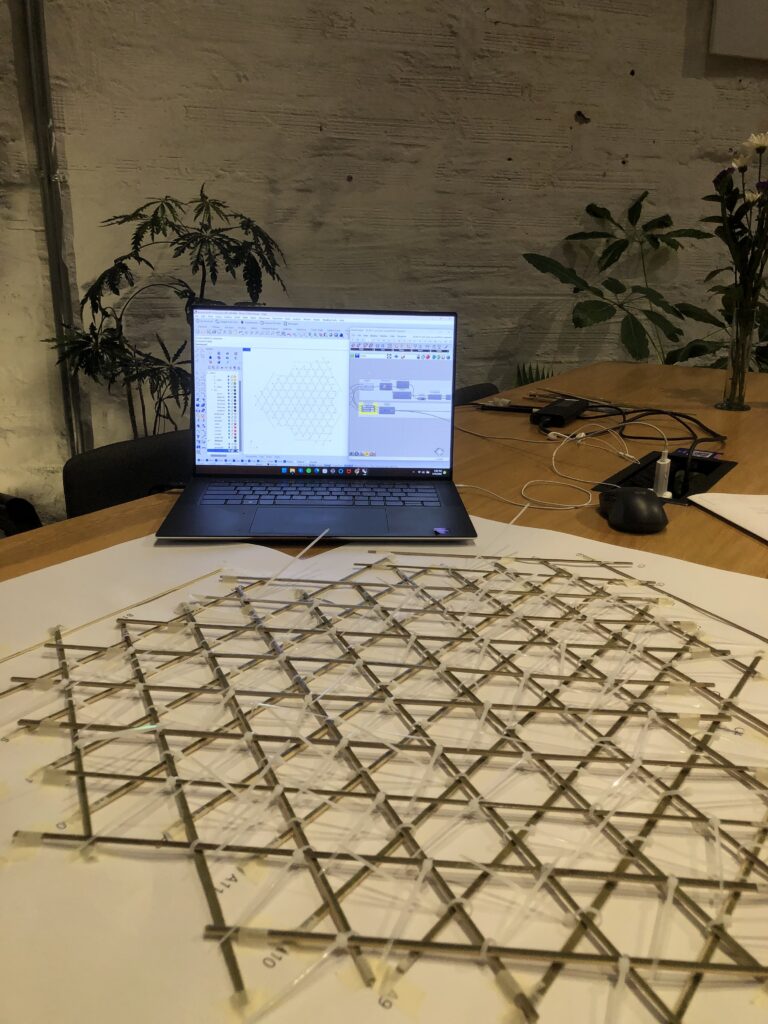

The pavilion utilized Guadua angustifolia, an endemic species from Colombia known for its structural strength and flexibility, which is ideal for such organic forms. Using Grasshopper’s built-in components and the Kangaroo plugin, which simulates the physical behaviour of geometries under gravitational and applied forces, the design process began with a hexagonal grid. This virtual grid mimicked how the structure would be assembled on the ground. We applied forces towards the centre of the grid at three equidistant points along the perimeter to simulate the dynamic responses of the structure. As these forces were introduced, the bamboo gridshell deformed into a form resembling the one predicted by the Kangaroo simulation. However, the bamboo’s inherent heterogeneity – such as its nodules and variations in thickness – resulted in specific areas exhibiting greater curvature than anticipated in the digital model.

This variation highlights the need for hands-on involvement during construction, where continuous testing of the bamboo’s behaviour is crucial. Back in the Grasshopper environment, the digital model can be adjusted to reflect these new findings, forming a feedback loop. We ensure better accuracy before final assembly by analyzing the minimum curvatures and pre-testing individual bamboo strips. Moreover, to accommodate the natural irregularities of the material, all bamboo strips are cut slightly longer than specified. This provides a buffer, compensating for areas where the bamboo may not bend or fit as expected.

final result

design process

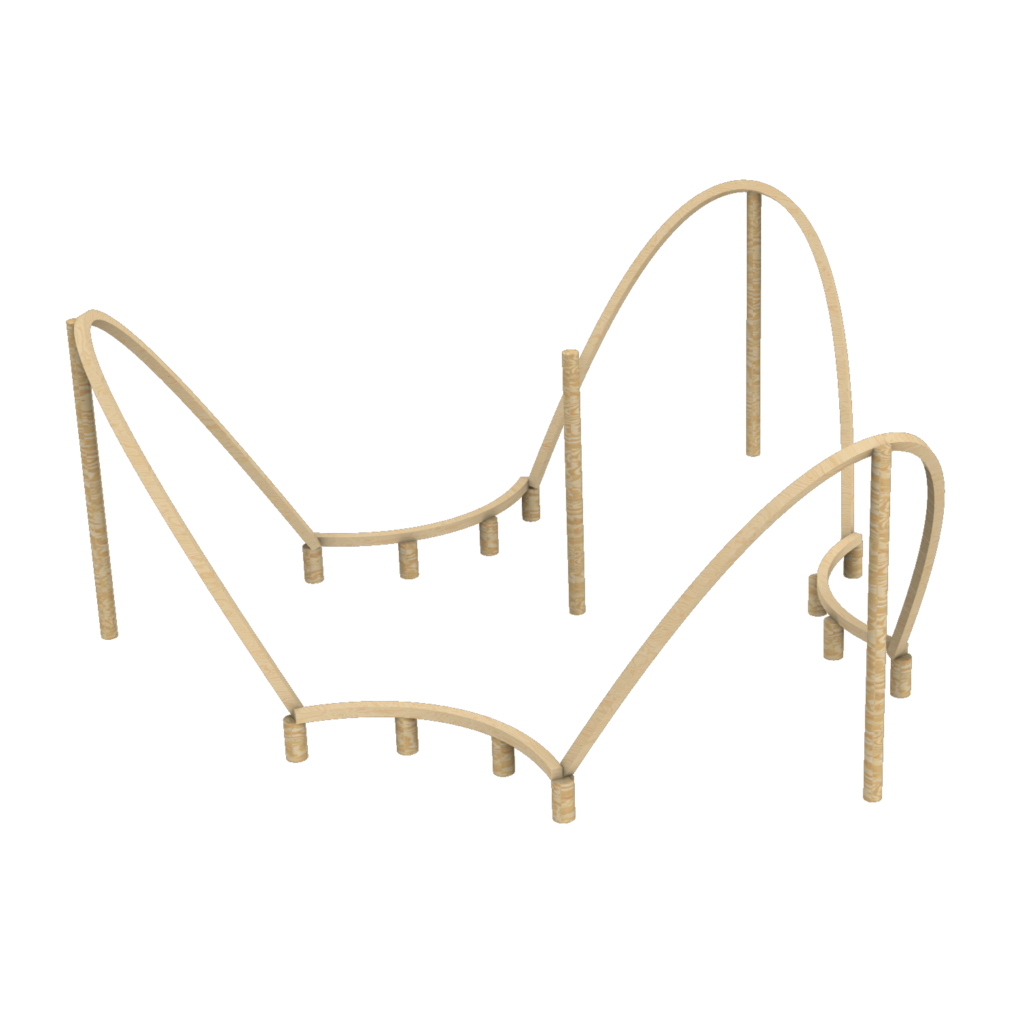

fabrication plan – pop-up gridshell

fabrication process – pop-up gridshell

construction steps (Fologram/Grasshopper):

blue: hexagonal grid “on the ground” was designed in Grasshopper and discretized in Weaverbird;

red: the anchor points shift towards the centre of the structure, causing the shell to “pop up” and stand upright;

yellow: placing the entrance.

construction process

team

Course Facilitators/Tutors: Camila Calegari Marques, Mansur Arevalo;

Tacuara Leaders: Camila Dutra, Urabá del Sol Ponzone;

Tacuara Team: Exneider Madrid, Alvaro López, Adolfo Salazar, Jeimer Guarin, Fernando Enamorado, Cristian Morales, Camilo Ocampo;

Construction Team: Camila Calegari Marques, Mansur Arevalo, Urabá del Sol Ponzone, Camila Dutra, Alvaro López, Juliana Saenz, Paola de Gracia, Luis Santiago M. Ramírez, Celina Llerena, Daniel Rua Calle, Daniel Pineda, Santiago Montoya, Carlos Esteban, Carlos Pinzon, Elizabeth Valencia, Tatiana Sierra, Alex.